Can physical products be designed and developed by teams working together virtually, from home? At the beginning of the COVID-19 pandemic, one-third of the employed American workforce worked from home. Despite this, only 3% of those were from the manufacturing sector. The field of physical product design had not previously attempted work-from-home models due to the need to access physical facilities for prototyping and testing, fear of leaking critical intellectual property assets, and the belief that it is easier to communicate technical details in person. Thus, my team and I used the widespread shift in virtual work to study the feasibility of this working style for physical product designers in the long term. We present innovative strategies that can be adopted by managers in this field and persisting challenges that still need to be addressed. This article is based on our paper recently published in Research in Engineering Design — you can read the paywall-free version here.

Remote physical product design is rarely studied nor attempted

Despite the wide range of research conducted on virtual collaboration and remote work practices in general, there are relatively few studies focusing specifically on product designers that work with physical products. Some say that this is because product designers are locally mobile and move around the office to communicate, collaborate, and maintain awareness — so they need to be co-located [1]. Others say that access to physical parts, prototyping tools, and testing laboratories is the biggest hurdle to remote physical design [2]; although the advancement in rapid prototyping tools like 3D printers may help to overcome this [3]. One of the most common arguments may seem less related to physical products — scholars argue that physical distance reduces communication frequency [4] and chance encounters with people from other teams [5]. These encounters are critical for innovative design: they can help to generate new ideas [5], share “tacit knowledge” across teammates [6], and reduce the complexity of shared mental models [7].

We interviewed 20 physical product designers shortly after the transition to virtual work

To fill this gap in the literature and investigate the applicability of these theories to current product design teams, we interviewed 20 physical product designers from June to August of 2020, closely after the switch to remote work. We targetted those who worked in a team to build a hardware product; our final sample consisted of 7 women and 13 men, from 16 different companies and 10 industries, spanning roles from entry-level to vice president.

We aimed to answer the following research question: how have virtual working conditions impacted hardware-dependent product designers? We asked designers about their background and experience with remote work prior to the pandemic; the challenges they experienced while working remotely, any strategies they devised to mitigate them; their attitudes towards virtual work; and their team dynamics.

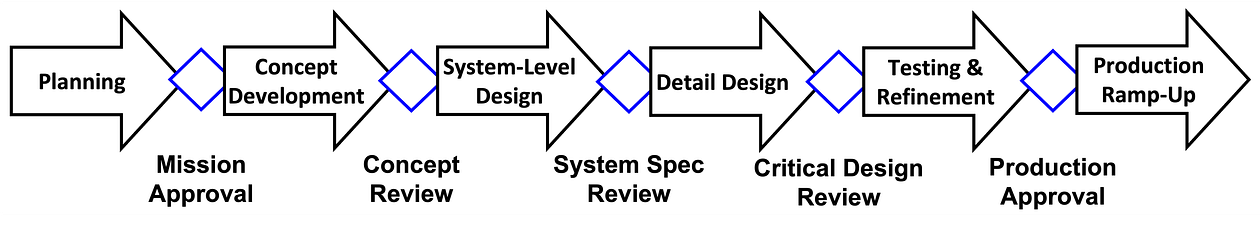

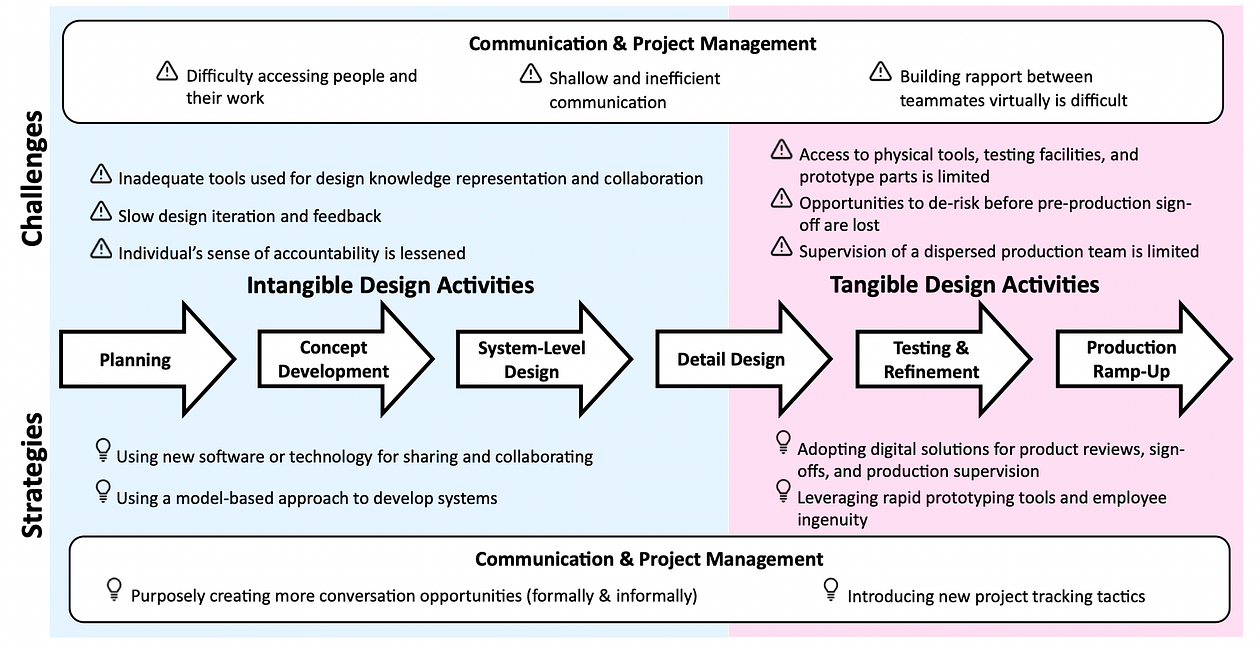

We analyzed these interviews iteratively, drawing out common challenges and re-occurring tools and strategies. As a framework to present these results, we began by matching each challenge and strategy to a phase of the generic product design process [8], shown below. However, we noticed that many challenges were similar across multiple phases, and a more useful breakdown would be to focus on Intangible Design Activities (an activity specific to product design that does not rely on physical products, prototypes, tools, or facilities) vs. Tangible Design Activities (an activity specific to product design that does rely on these physical artifacts). Lastly, we found challenges and strategies related to Communication and Project Management more broadly; while these challenges may not be specific to physical product designers, they are still critical for product success.

In the following sections, I provide a brief description of the challenges and strategies discovered for Intangible Design, Tangible Design, and Communication and Project Management activities, along with quotes from the designers. You can find a more in-depth discussion in the paper.

Intangible Design Activities

Intangible design activities are those specific to product design that does not rely on physical products, prototypes, tools, or testing.

Challenge 1: Inadequate tools used for design knowledge representation and collaboration. Participants were forced to rely on digital design tools, but many found these tools unsatisfactory; specifically in terms of virtual whiteboards and Computer Aided Design (CAD) accessibility.

The whiteboard is greatly missed … to meet with the customer and [share] ideas with them because that’s really the best tool to work together…For instance, we have to [present] a lot of lifecycle [analysis], use case analysis, scenarios. It’s all stuf from a whiteboard. We can do things like that with an application like VISIO, WebEx, et cetera, but it’s not the same. (Participant 20)

Challenge 2: Slow design iteration and feedback. Designers also noted that working remotely meant it took longer to get feedback from their peers on a design, which slowed down iteration. This was most notable when brainstorming.

And usually what happens during a brainstorming meeting is [we get] synergies happening when you’re talking about different concepts. Sometimes you come up with something on the spot, combining two or three concepts. [In a virtual setting] we have difficulty in formulating that…. (Participant 1)

Although it also slowed designers down when working on modeling a product.

The single most challenging thing I think would be the back and forth that my boss and I used to have on questions I had or suggestions I had regarding the modelling that I do…. Now it’s not quite the same. I can send a screenshot over Microsoft Teams or something, and he’ll respond, but it’s a lot harder without being able to just point on a screen. (Participant 7)

Challenge 3: Individuals’ sense of accountability is lessened. Designers and managers both mentioned that they needed to be more diligent in taking on and assigning accountability for small tasks, to ensure things were not falling through the cracks.

It’s a little bit less likely that people are thinking like, ‘Oh, am I going to be the one that should do that’ and kind of ask, ‘Hey, who’s following up on that.’ So I am noticing…you have to be very diligent at the end to be like, ‘here are the actions you’re responsible for…can you do this?’ (Participant 11)

Strategy 1: Using new software or technology for sharing and collaborating. While many designers remained unsatisfied with virtual whiteboard alternatives, others found success using lightweight CAD sharing tools, such as Onshape, which allowed other team members to easily and quickly review the model.

We used Onshape for CAD, and what was actually really great is they have a ‘follow’ command. So if you have the Onshape assembly document open, we can double click that person’s icon at the top [if] they’re on the same tab, and your screen will follow their mouse and all the emotions they’re doing… (Participant 3)

Strategy 2: Using a model-based approach to develop systems. Using a model-based approach means that all the product’s information is captured in models instead of documents, forming a single source of truth for the product. This helped designers to manage complexity and improve traceability when working from home, as every designer could access the same information.

Tangible Design Activities

Tangible design activities are those activities within product design that build, test, or otherwise require the use of physical products and tools.

Challenge 4: Access to physical tools, testing facilities, and prototype parts is limited. Perhaps the most obvious barrier to remote physical product design is the access to physical resources. Designers spoke about the lack of access to benchmarking resources, such as car parts, and difficulty in verifying product aesthetics.

Normally in the office, we have somebody … in charge of checking colours of printing and colours of product.… Because I don’t necessarily have that experience or knowledge on how to evaluate it, I missed those types of things. (Participant 15)

Challenge 5: Opportunities to de-risk before pre-production sign-off are lost. Many product design teams use design reviews to gather final feedback on a product before production begins. Designers noted that they received less feedback and there was less engagement when these reviews were conducted virtually and team members couldn’t physically hold the product.

Because I’m not sending [prototype parts] to anybody … [while] I can evaluate most of the specs because I’m familiar with the product, … there are always things that other people will fnd that are not necessarily in the spec or that we haven’t actually thought about before. (Participant 15)

Further, it was even more challenging to conduct user testing virtually.

Especially when it comes to products that have a hardware component, it’s really hard to simulate, or at least tell your users to imagine that they’re holding a product and imagine that they’re interacting with a patient. (Participant 8)

Challenge 6: Supervision of a dispersed production team is limited. Whether manufactured in-house or externally, many design teams have designers overseeing the manufacturing process or supervising production staff. Our participants described being unable to travel to overseas manufacturing facilities and having difficulties communicating with all production shifts.

If there’s an engineering change to communicate across three different shifts in a day, [up to] four different shifts in a week when you’re not allowed to interact with [production workers] face-to-face, that was hugely challenging. (Participant 9)

Strategy 3: Adopting digital solutions for product reviews, sign-offs, and production supervision. Product designers needed to adopt digital alternatives for their processes of physically marking up design drawings, communicating test results with technicians, collecting testing data, and supervising manufacturing staff. They implemented PDF markups, more detailed test reports, automated test data tracking and charting, and supervisory video streams.

We were able to set up … a bunch of really good camera setups around the lines. We were able to have multiple Zoom calls basically going on in parallel. We’d have a couple diferent rooms; one [is] maybe focusing on assembly issues, one might be focusing on calibration issues.…We are interested in seeing their hands and the tools that they’re using to say, ‘Oh, you’re not using a torque driver’ or, ‘Oh, you didn’t put Loctite on that.’ (Participant 2)

Strategy 4: Leveraging rapid prototyping tools and employee ingenuity. Without access to their company labs, and with the supply chain issues brought about by the pandemic, many designers created mini prototyping studios in their homes.

…there were some tests [my employee] wanted to do that didn’t [risk sensitive intellectual property], so he needed me to fnd a long clear tube … a fan, a power converter, and a few other parts.… I found the parts, [and] dropped them of, and he’s got a woodwork shop in his garage, so he kind of just went at it. (Participant 11)

Communication and Project Management

Communication and project management are major themes that play a role in all phases of the product design process; every designer we interviewed discussed challenges within these themes.

Challenge 7: Difficulty accessing people and their work. Designers shared that communication seemed to become more formal when working virtually; they had a fewer impromptu, informal interactions; they were less exposed to projects happening within other teams, and they lost the mutual sense of project progress.

There is a … miss [of] the random conversations. Just fnding out that, ‘Oh, you’re dealing with that problem….we had that problem three years ago… let me send you an important report on that.’ The serendipitous interactions dropped down. (Participant 11)

Challenge 8: Shallow and inefficient communication. Participants reported that the lack of non-verbal communication reduced the quality of meetings, made it hard to tell if everyone was on board with an idea, made it hard to speak in large meetings, and posed accessibility issues for some individuals.

I had a meeting where a manager had a really strong opinion that I couldn’t tell if everybody else agreed with him or not.… That’s kind of weird because normally, you can kind of look around and get a sense of [what] other people are thinking. (Participant 5)

Challenge 9: Building rapport between teammates virtually is difficult. Complex products require input from many different teams, and a strong product manager to collect and consolidate this information. However, our participants found it hard to build the needed relationships virtually to efficiently gather data and updates from all teams.

…because there are so many stakeholders in system-level projects… it’s just hard to get everybody to give you the information that is needed to make a project decision and move on. (Participant 5)

Strategy 5: Purposely create more conversation opportunities (formally & informally). Almost all of the designers we spoke to mentioned that communication frequency decreased when working from home. To overcome this, teams had to create explicit opportunities for this knowledge transfer to happen: from weekly check-in meetings to post-meeting watercooler conversations in breakout rooms, to newly scheduled process and tool meetings.

[We have a] tech club for discussions about our process and our tools and things that weren’t specifc to a single project but were more relevant for the entire team. Those conversations used to happen on the edges of some of our engineering review meetings … the tech club makes a space for some of those conversations that we are already having but then stopped having once we went fully virtual. (Participant 5)

Strategy 6: Introducing new project tracking tactics. Design teams started using new methods to visually track project progress, as they could no longer just stop by a co-worker's desk for an update.

People can schedule their own tasks and see what’s going on and see what connects….it’s been really helpful for me to see what my team is working on and make sure that everyone’s on the same page with the priorities. (Participant 14)

I’ve summarized all of the challenges and strategies discussed in the following diagram.

COVID-19 allowed product designers to realize the feasibility of a more flexible working style

The designers we spoke to noted that they didn’t previously believe that it would be possible to work from home in their role, nor were their organizations prepared with the policies and practices needed to do it effectively.

Once in a blue moon kind of thing that people would work from home. (Participant 17)

Because we are such a hardware-focused company, we had generally discouraged [working from home]. (Participant 2)

However, being forced to work remotely during the pandemic made many product designers realize that it was possible to develop new physical products while working almost entirely from their homes.

A lot of work can be done remotely. I think that [COVID-19] just forced the decision for a lot of employers. And I think they realized that ‘Hey, it’s doable in a lot of cases.’ (Participant 16)

Yet some noted that due to their reliance on physical products, working entirely remotely may still be out of reach.

We absolutely have to have access to a test lab. [I] need certain machines and equipment to be able to do my job as a mechanical engineer. So I don’t think that we’ll ever be able to move entirely to a remote work model, but I do think that we can probably scale down at some point. (Participant 12)

Finally, most of the designers we spoke to shared that they believe a hybrid working model is the best way forward.

I can totally see it being divided by like: I’ve got these three meetings; I’m going to come in on Wednesday and have these three meetings. And then, for the rest of the week, I’m doing my CAD work, which I don’t need to interact with somebody…I think that will continue into the future because there’s no reason not to. (Participant 9)

Key Takeaways

Although long believed to be ineffective, we found that physical product design is possible while working from home. Tangible Design activities — those that include physical products, tools, and facilities — are still the most challenging tasks to complete. These unaddressed challenges, such as inadequate tools for design representation, slow design iteration, loss of de-risking opportunities before production, and difficulties accessing people and their work, present areas that should be focused on by design managers and researchers in the future. We’ve also collected innovative strategies that design managers can implement immediately:

- Adopt virtual whiteboards (particularly with an investment in hardware tablets), and lightweight CAD sharing tools (such as Onshape) for design collaboration.

- Move towards a model-based systems approach when developing complex products, so everyone can access the single source of truth.

- Adopt digital solutions (such as pdf redlining, automatic charting of test results, and zoom stream supervision) for activities that normally require in-person presence.

- Invest in rapid prototyping tools to allow designers to prototype from home studios.

- Create purposeful opportunities, in the form of new meetings or additions to existing meetings, for watercooler conversation and spontaneous knowledge transfer.

- Use visual, shared project tracking tools to align priorities and keep track of everyone’s progress.

I want to thank all of the collaborators on this project: Kimberly Lai for her help writing and revising this manuscript; James Chen, Safa Faidi, and Kevin Leonardo for their input on the original version; and, as always, Alison Olechowski for her extraordinary supervision.

If you found this interesting and would like to keep up with my work through the rest of my Ph.D., you can find me on Twitter (@_sharonferguson) and on my website.

References

[1] Bellotti V, Bly S (1996) Walking away from the desktop computer. CSCW. https://doi.org/10.1145/240080.240256

[2] Velzen E Van, Olechowski A (2021) Investigation of remote work for aerospace systems engineers. Annual INCOSE International Symposium 31:1. https://doi.org/10.1002/j.2334-5837.2021.00872.x

[3] Camburn B, Viswanathan V, Linsey J et al (2017) Design prototyping methods: state of the art in strategies, techniques, and guidelines. Des Sci 3:1–33. https://doi.org/10.1017/dsj.2017.10

[4] Leenders RTAJ, Van Engelen JML, Kratzer J (2003) Virtuality, communication, and new product team creativity: a social network perspective. J Eng Technol Manag JET-M 20:69–92. https://doi. org/10.1016/S0923–4748(03)00005–5

[5] Sailer K (2011) Creativity as social and spatial process. Facilities 29:6–18. https://doi.org/10.1108/02632771111101296

[6] Mascitelli R (2000) From experience: harnessing tacit knowledge to achieve breakthrough innovation. J Prod Innov Manag 17:179– 193. https://doi.org/10.1016/S0737-6782(00)00038-2

[7] Schmidtke JM, Cummings A (2017) The efects of virtualness on teamwork behavioral components: the role of shared mental models. Hum Resour Manag Rev 27:660–677. https://doi.org/ 10.1016/j.hrmr.2016.12.011

[8] Ulrich KT, Eppinger SD, Yang MC (2020) Product design and development, 7th edn. McGraw-Hill Education, New York